- About us

- Services Offered

- Research Activities

- Significant Technologies

- Awards

- List of Facilities Available

- Technology Write up

- Scientists

About Us

CSIR-CEERI, Pilani (Rajasthan)

CSIR-Central Electronics Engineering Research Institute (CSIR-CEERI), Pilani (Rajasthan), (www.ceeri.res.in), is a premier institution in the country and a constituent national laboratory of Council of Scientific and Industrial Research (CSIR), New Delhi, established in 1953 by Govt. of India, for the advancement of Research and Development (R&D) in the field of Electronics. It has made immense contributions to the growth of electronics and allied engineering in the country and has established state-of-the-art infrastructure in the R & D areas of Microwave Tubes, Plasma Devices, MEMS and Microsensors, Optoelectronics Devices, Microelectronic Processing and Fabrication, VLSI Design, LTCC Technology, Nano Structures, Power Electronics, Industrial Process Control, Agri-electronics, Instrumentation and Embedded Systems and serving the nation since its inception.

Vision of the Laboratory

To become a globally renowned coveted destination for scientific knowledge, research excellence and innovative technology in electronics as well as allied sciences & engineering, with high social and strategic impact.

Mission of the Laboratory

- Support and nurture creative excellence of individual scientists.

- Synergize individual brilliance with purposive collective team-effort for meeting mission-mode objectives.

- Innovate to enable India to have a leadership role in strategic sectors.

- Collaborating with industry for innovative product development.

- Becoming source of globally competitive technology in the areas of electronics and allied sciences and engineering.

Mandates of the Laboratory

- Excellence in scientific research in the areas of electronics and allied science and engineering.

- Mission-mode initiative for innovative electronics and allied technologies to foster inclusive development

- Technology delivery for strategic requirements and industrial needs.

- Motivating disruptive innovations for entrepreneurship in the area of electronics and allied engineering.

- Networking with other CSIR labs, industries, research and academic institutions for multi-disciplinary innovation.

- Academic and scientific pursuit for nurturing talent and manpower development

Regional Centres

CSIR-CEERI Chennai Centre is one of the three regional centres of CSIR-CEERI located at CSIR Madras Campus, Taramani, Chennai-600 113. Out of other two Centres, CSIR-CEERI Delhi Centre is located at A/93-94, Naraina Complex, Naraina Industrial Area, Naraina, New Delhi-110 028 and the CSIR-CEERI Jaipur Centre, an Incubation-cum-Innovation Hub, is located at CFC-1, Malviya Industrial Area, Jaipur-302 017, Rajasthan.

CSIR-CEERI Centre, Chennai

Established in 1974, the CSIR-CEERI Chennai Centre is a pioneering institute in developing indigenous technologies for automation of Indian process industries. The Chennai Centre had developed many novel automation systems using state-of-art techniques for pulp & paper, food, leather, chemical & plastic industries. Later, the Centre had ventured into development of machine vision systems, process automation systems, visible & near infrared technologies, terahertz technologies and renewable energy related technologies for societal needs. CEERI Centre is presently involved in major activities in the areas of Signal Analytics, Renewable Energy with Internet of Things (IoT) and Terahertz in Integrated Systems under the broad area of Cyber Physical Systems of CSIR-CEERI and Interface & Skill Development Programmes in IoT, Machine Learning, etc.

- Thrust Areas of Research

- Signal Analytics

- Renewable Energy with Internet of Things (IoT) and

- Terahertz in Integrated Systems

- A Bird’s Eye View of a Few Recent Technologies

- Technologies Developed & Transferred

- Food Processing Industry

- X-ray Imaging based Mango Sorting System

- Electronic Weighing based Fruit Sorting System

- Plastics Industry

- Plastic Waste Sorting System for recycling of Polyethylene Terapthalate (PET) Materials

- Plastic Waste Sorting System for Five Types of Plastics

- Automobile Industry

- Mathematical Model for Human Fatigue Detection using Physiological Parameters

- Security & Surveillance

- Dual Energy X-ray Image Analysis Technique for Material Discrimination

- Clean & Renewable Energy

- IoT enabled Solar Tree

- Food Processing Industry

- Technologies Developed

- Food Processing Industry

- Smart System for Grading and Sorting of Fruits

- Smart-camera based Machine Vision System for Real-time Inspection and Sorting of Biscuits

- NIRS based on-line monitoring of Free Fatty Acid (FFA) in Edible Oil

- Image Processing Technique with X-ray Imaging System for on-line Inspection & Detection of Foreign Objects in Rava Packets

- Clean & Renewable Energy

- Portable Solar Products for Decentralized Applications

- Food Processing Industry

- Technologies Developed & Transferred

Services Offered

CSIR-CEERI Chennai Centre offers the following services to cater to the needs of various Industries and Educational Institutions:

- Contract Research & Development.

- Consultancy.

- Technical Services.

- Training.

- Skill Development Courses in IoT, Machine Learning, etc.

CSIR-CEERI Chennai Centre offers Contract Research & Development for the development of machine vision systems, process automation systems, visible & near infrared technologies, terahertz technologies and renewable energy related technologies for societal needs in the areas of Renewable Energy with Internet of Things (IoT), Signal Analytics and Terahertz in Integrated Systems under the broad area of Cyber Physical Systems, through specific contractual arrangement agreed upon for the purpose.

CSIR-CEERI Chennai Centre welcomes both user industries and equipment manufacturing companies to establish mutually beneficial linkages in respect of R & D projects of industrial application for various industries under the Contract Research & Development programme.

The consultancy services shall be extended to interested clients in an area of expertise of the Centre, preferably in "Thrust Areas of Research". There are two categories of consultancy viz., (1) Advisory Consultancy where in the services would involve scientific, technical, engineering or other professional advice, provided to a client purely on the basis of available expert knowledge and experience of the personnel, rendered outside CEERI and not envisaging use of any facilities of the laboratory and also not involving any kind of survey, detailed study or report preparation/submission and (2) General Consultancy where in the services shall comprise scientific, technical, engineering, or other professional advice/assistance based on the available knowledge base/expertise of the Centre and envisaging only minimum use of laboratory facilities for essential experimentation needed to meet the objectives of the consultancy assignment.

The following technical services shall be rendered to clients/customers, assistance of a minor nature based on available knowledge, expertise, skills and facilities of the Centre,

- Training.

- Technical assistance of advisory nature

- Fabrication of special products.

- Repair & maintenance.

- Supply of information/database.

for various user industries and equipment manufacturing companies.

The Centre offers training to the students of various academic institutions of the country for doing short-term projects/dissertation works in the areas of the interest of the Centre for their under graduate engineering, post graduate and doctoral programmes, subject to the availability of manpower and space of the Centre.

CSIR-CEERI Chennai Centre is conducting various Skill Development Programmes/Courses in Internet of Things (IoT), Machine Learning, etc.

For further details, please contact

The Scientist-in-charge

CSIR-CEERI Centre, CSIR Madras Complex, Taramani, Chennai-600 113

Ph.: 91-44-2254 4582/2281/4580, Fax: 91-44-2254 1889

Email: sicceeri@csircmc.res.in

Research Activities

Most of the CSIR-CEERI Chennai Centre’s projects are aimed at quality enhancement, reduction in wastage, optimum energy usage and savings in raw materials.

Some of the industries have approached the Centre for possible solutions for the quality improvement of their products, through external sponsorship or consultancy. A couple of projects, out of a few projects taken-up, have been completed with external funding by industries.

The Centre is presently having a two storey main building located inside the CSIR Madras campus. In the first floor, R&D divisions including the R&D infrastructure facilities like Optical Laboratory Facility, Near Infrared (NIR) Instruments Laboratory, Image Processing Laboratory and Embedded System Development facility, etc are located. In the ground floor, infrastructural facilities like Workshop, CAD section, etc., and a Training Hall, which is utilized for training the entrepreneurs, conducting lectures, technical presentations, organizing workshops, student training, etc., are located. In addition to the above, an R&D Prototype Laboratory Facility, including Sophisticated Terahertz Photonics Laboratory is housed in a shed of 400 sq.mtr. built-in area, located inside the CSIR Madras campus, near to CSIR-CEERI Chennai Centre.

The Centre has established latest state-of-the-art facilities and infrastructures through sponsored funding in advanced technologies like Image Processing, Machine Vision, Real-Time Imaging, DSP/FPGA, IR Signal Analysis & Instrumentation, Terahertz Spectroscopy and Photonics.

The Centre has ambitious plans to develop machine vision/IR signal analysis & instrumentation/terahertz spectroscopy based sensors/system technologies for quality assessment/assurance to help in reducing wastage, optimize energy usage, enhance productivity, value addition and compete in global markets.

The Centre plans to develop spectral technologies for IR range for milk adulteration and food adulteration, NIR based technologies for seed germination & edible oil quality and mid IR based technologies for soil quality, food quality including milk.

Security and Surveillance technologies are one of the key areas where technology intervention can create a significant impact in India. Currently, our country heavily depends on imported technologies for meeting the requirements in this sector. Similarly, most of the X-ray baggage scanners employed in the airports are imported systems. CSIR-CEERI with its expertise in THz and X-ray imaging technologies is uniquely poised to develop indigenous technological solutions for security and surveillance applications. For the development of THz and X-ray based security and surveillance technologies, CSIR-CEERI is planning to collaborate with the various potential stake-holders. The Centre aims to become a Terahertz Centre in the future, to cater to the needs of the industries and institutions in South India.

The Centre takes up sponsored, collaborative, grant-in-aid projects under contract research & development from private and government agencies for the development of electronic systems at an affordable cost. The Centre also undertakes consultancy projects and technical services to fulfill the specific needs of the industries in its areas of expertise.

The Centre has close association with various industries, academic institutions, and professional bodies. The Centre is located in Chennai, a metro city well connected with the rest of the world, which has the advantages in terms of having more industries. Closeness to nearby cities like Bangalore and Coimbatore is also fetching good opportunities for the Centre to explore the industry contacts and considerable service oriented sectors.

In view of the above experience, expertise and proximity to various academic institutions & industries, CSIR-CEERI Chennai Centre will play a pivotal role in formulating some important projects to develop technological solutions and also through skill development programmes, which will benefit the society as well as CSIR.

- Completed Projects

- On-Going Projects

An on-line automatic sorter to identify and segregate different types of plastics was developed with funding from Ministry of Environment & Forests, New Delhi. This helps in easy management of solid plastic wastes for recycling. The technology for recycling of PET materials was transferred to an industry. The know-how on NIR spectroscopy based plastic waste sorting system for five types of plastics was also transferred to an industry.

An on-line mango sorting system using soft x-ray imaging was developed with funding from DST, New Delhi, for analyzing export variety mangoes for internal disorders and infestation like seed weevil and spongy tissue, and sorting out the defective fruits. This is useful in sorting best quality mangoes for export and reducing rejection by foreign customers.Technology on ‘X-ray imaging based mango sorting system’ was transferred to an industry.

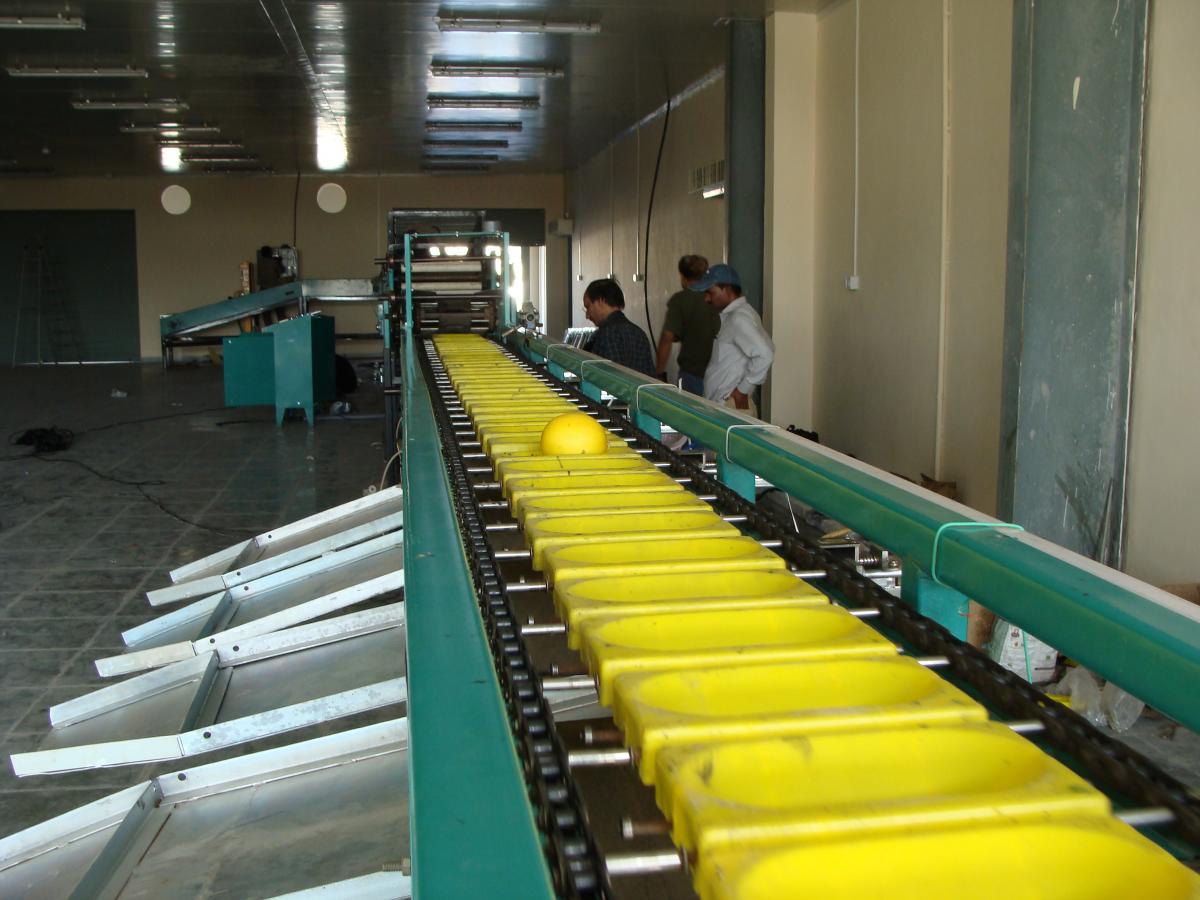

A grading system to sort mangoes based on colour, size and weight was developed with funding from NHB, Gurgaon. The technology on ‘Electronic weighing based fruit sorting system’ was transferred to an industry. One unit has been fabricated by the licensee and supplied to Maharashtra State Agricultural Marketing Board (MSAMB) at Beed, Maharashtra and commissioned.

A computer aided microscopic inspection system for authentication of herbal plant raw materials was developed jointly with IICT, Hyderabad and Arya Vaidya Sala (AVS), Kottakkal and installed at AVS.

The technology for rapid and non-destructive determination of quality parameters of the edible oil by using near infrared reflectance spectra and chemometric methods was developed with funding from DST, New Delhi and Kaleesuwari Refineries Ltd, Chennai as user industry. The know-how on ‘NIRS based on-line monitoring of Free Fatty Acid (FFA) in edible oil’ is ready for technology transfer.

A system for on-line surface inspection of hot rolled steel strips was developed in collaboration with R&D Centre for Iron & Steel (RDCIS), SAIL with funding from DIT, New Delhi and implemented at Bokaro Steel Plant.

The Centre synergies with CSIR-CEERI, Pilani, by being part of Supra Institutional Project on “Technology Development for Smart Systems” and developed Smart systems for sorting and grading of fruits like apple and mango, A smart-camera based machine vision system for real-time visual quality inspection and sorting of biscuits, An acousto-optic tunable filter (AOTF) based near infrared spectrophotometer and Thermo-acoustic power generator.

The Centre has completed an EMPOWER project for the design of ‘Non-tracking solar concentrators based on sub-wavelength gratings to reduce the cost of solar photovoltaic energy’.

Non-network project on ‘Development of compact low cost Terahertz imaging system based on CW photo-mixing and proof of concept demonstration of non-intrusive package inspection’.

Sponsored project on “Development of image processing technique for on-line detection of foreign objects in rava (sooji) packets and integration with X-ray imaging system”.

Under EMPOWER Scheme as a Phase-II, ‘Large scale fabrication of sub-wavelength nano gratings for energy and bio-photonics applications (LaSEB)’.

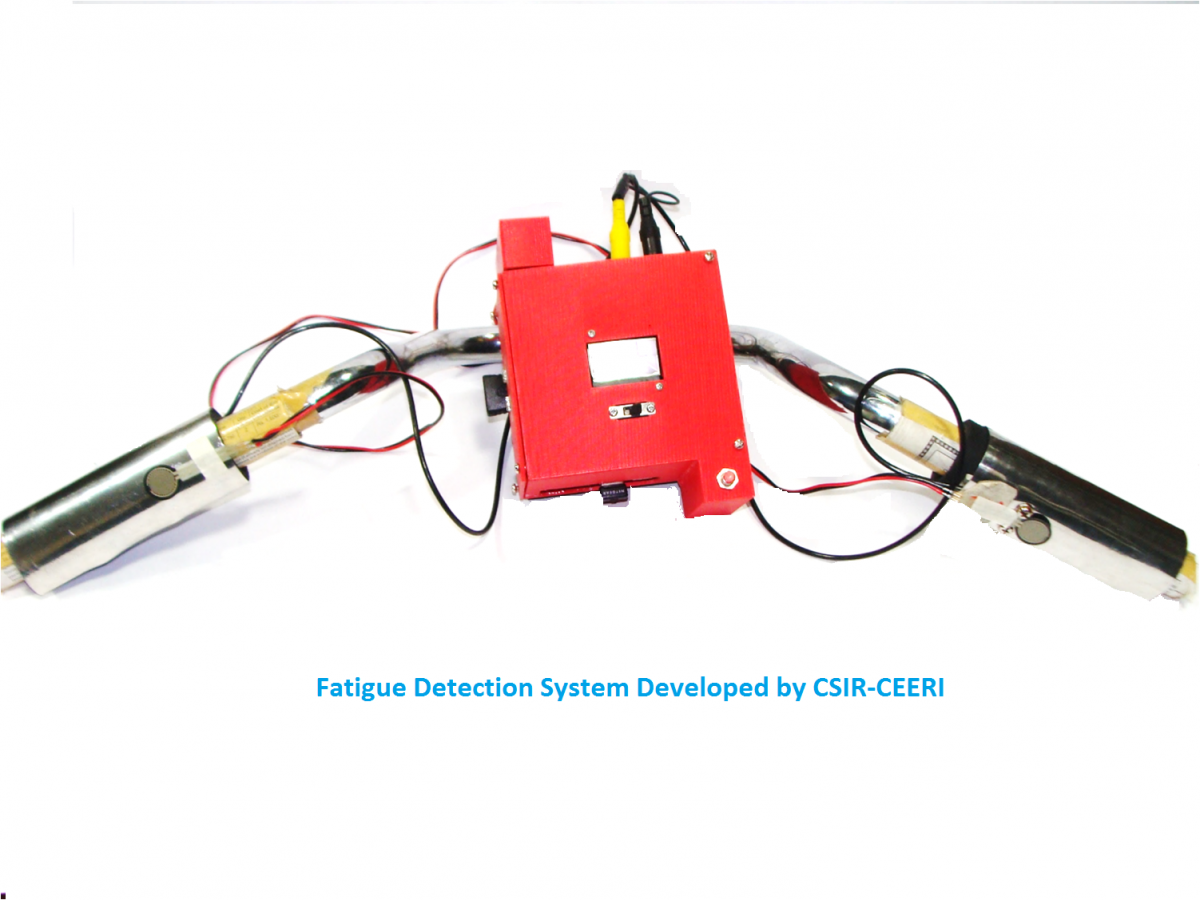

Sponsored project on “Development of mathematical model to establish correlation between human fatigue and measured physiological parameters”.

Grant-in-aid project on “Rapid Real time Blood Pressure Measurement and Hypertensive Predisposition Diagnostics using Pulse Transit Time and Blood Pressure Variability”.

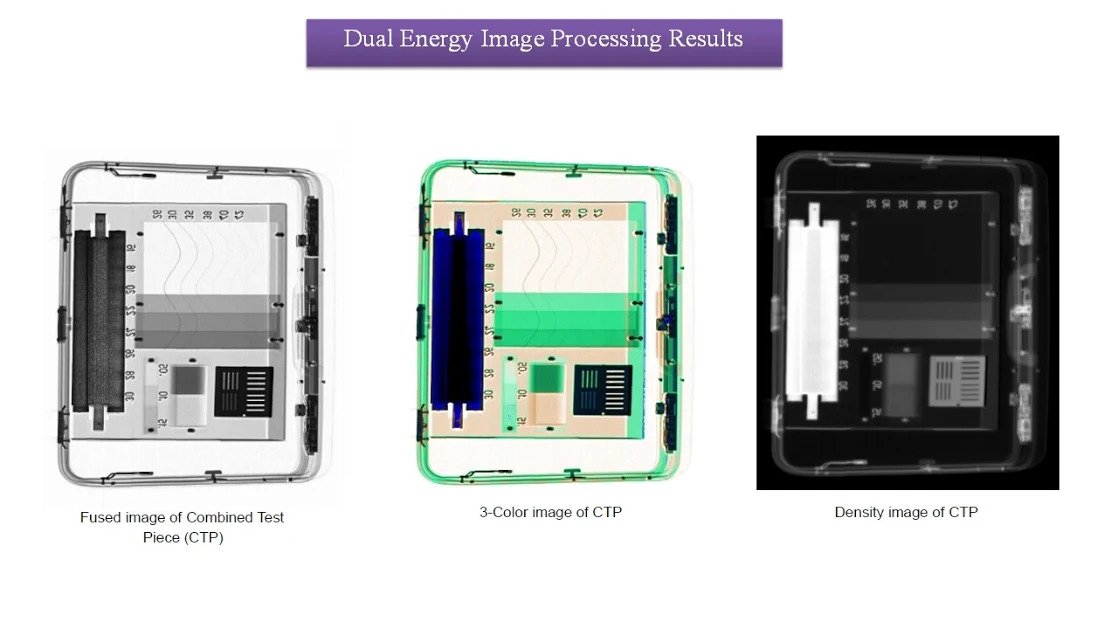

Collaborative project on “Material Discrimination based on Atomic Number of Scanned Items using Dual Energy X-Ray Images”.

Activity on ‘Development of GaN based high brightness LEDs for solid state lighting applications’ under Network project of CSIR-CEERI on “Efficient silicon photovoltaics with smart electronics and lighting systems – a TAPSUN project”.

Network project on “Creating intellectual property & capabilities for the development of improved security features and substrates for the Indian currency notes (FUTURE)”.

CSIR-NMITLI project on “Development of integrated technological solutions for security and operations based on UV sensor technologies”.

Activity on “Formulation of standards and specifications for digital data collection”under the 12th Five Year Plan Project on “Effective Application of Community Health Efforts through New Age, IT based Modes (EACH-IT)”.

Consultancy project on “Design optimization of solar tree”

Consultancy project on “Physical and chemical analysis of aspirin delayed release tablets using microscopy, terahertz and FTIR spectroscopy”

Sponsored project on “Development of Computer-aided Machine Vision System for Authentication of Herbal Plants for Ayurvedic Medicine”

Collaborative Research Project on “Solar Photo-voltaic Thermal (PVT) Co-generation System”

CSIR’s Fast Track Translational (FTT) Project on “Handheld Milk Quality Analyser”

Non-imaging optics based low concentrating photovoltaic thermal (LCPVT) hybrid system.

Indo-UK Joint Project on “Concentrated Photovoltaic (CPV) assisted tandem Artificial Photosynthetic (AP) device for effective solar to chemical conversion” (DST & UK India Education Research Initiative).

Energy Harvesting Smart Windows using High Contrast Grating Based Planar Concentrators for Building Integrated Photovoltaics.

Health Care Home Assistance Systems

Human Fatigue and Drowsiness Detection Applicable to Drivers and Industrial Workers under CSIR Artificial Intelligence Mission Programme

AI based Health Care Systems under “Intelligent Systems (IS) – Intelligent Technologies and Solutions” of CSIR Artificial Intelligence Mission Programme

Sponsored Project

Sponsored project on “Detection of Threat Objects in Baggage and Food Quality Inspection using Image Processing & Pattern Recognition Techniques for Single View X-Ray Scanners & Development of near 3D Image Visualization Software for Dual View X-Ray Scanner”.

S&T Services

S&T Services – Student Training programme for the final year BE/B.Tech/MCA/ME/M.Tech/ M.Sc of various self-financing, private and government institutions.

Grant in aid project

Grant-in-Aid project jointly with CSIR-CLRI on "Automated machine vision system for leather surface quality discriminant function analysis, MeitY, New Delhi

Spectroscopic platform for Detection of Adulteration in Milk

NCP/FBR - Project Sanctioned by DG,CSIR

High Power Sub-THz compact source applicable for security screening and non-destructive evaluation (HP-SCAN).

Skill Development Program

Skill Development Programme on Video Analytics and Machine Vision System.

Significant Technologies Developed and Transferred

During initial period, the Centre has successfully completed various consultancies and sponsored projects under external sponsorship from many private industries as well as with in-house and grant-in-aid funding and transferred the developed know-how to various process industries. In these efforts, the Centre has involved various allied process industries and pulp & paper industries as end user industries and for conducting field trials of the developed systems. The developed technologies were transferred to many entrepreneurs for commercialization.

During the latter period, the Centre has ventured in to the development of machine vision technologies, NIR spectroscopy technologies and solar energy technologies. In these efforts, the Centre has involved various industries as end user industries and for field trials of the developed systems. The developed technologies were transferred to many entrepreneurs for commercialization.

The Centre has been making serious efforts towards transfer of the developed technologies to interested entrepreneurs for commercialization by utilizing the industry linkage established over the years. The Centre has been interacting with many interested entrepreneurs, mainly consisting of MSME industries. In most cases, the technologies have been demonstrated for their basic functionally in the laboratory or field-tested over a limited period in the user industries. These technologies require further improvements in terms of reducing the cost, improving reliability and addition of extra features for better marketability. This requires transfer of the technologies to entrepreneurs and supporting the entrepreneurs in improving the technologies to meet the market requirements.

Also, several entrepreneurs have visited the Centre at regular intervals to witness the demonstrations of the developed technologies for selecting technologies meeting their requirements. The fact that during the past one and half decade, the Centre was able to convince and transfer a significant number of technologies to various entrepreneurs shows the Centre’s bond with the industries. Recently two technologies have been commercialized with the assistance of the Centre.

Technologies Developed & Transferred/Process Released (2010-18)

Food Processing Industry:

- Electronic Weighing based Fruit Sorting System

Plastics Industry:

- Plastic Waste Sorting System for Five Types of Plastics

Automobile Industry

- Mathematical Model for Human Fatigue Detection using Physiological Parameters

Security and Surveillance

- Dual Energy X-ray Image Analysis Technique for Material Discrimination

Clean & Renewable Energy

- IoT Enabled Solar Tree

Healthcare System

- Computer-aided Machine Vision System for Authentication of Herbal Plants for Ayurvedic Medicine

Technologies Developed (2010-18)

Food Processing Industry

- Smart system for grading and sorting of fruits like apples, mangoes, etc

- Smart-camera based machine vision system for real-time inspection & sorting of biscuits

- NIRS based on-line monitoring of Free Fatty Acid (FFA) in edible oil

- Image processing technique with X-ray imaging system for on-line inspection & detection of foreign objects in rava packets.

Plastics Industry

- Infra-gauge with ‘O’ Frame Scanner for Cast Film

General Instrumentation

- Acousto-Optic Tunable Filter based NIR Spectrophotometer System

Technology Commercialized during the period 2010-18

- Electronic weighing based fruit sorting system technology was transferred to M/s. Stayfresh, Navi Mumbai. The licensee fabricated and handed over one electronic weighing based mango sorting system to Sri Gajanan Cold Storage & Pack House, MSAMB, Beed, Maharashtra during 2014.

- The know-how of “Dual energy X-ray image analysis technique for material discrimination” was transferred to M/s. Krystalvision Image Systems Pvt. Ltd., Pune, Maharashtra. About 24 scanners were fabricated and installed throughout India by the licensee during 2017-18.

Technologies Developed & Transferred/Process Released (2000-10)

Pulp & Paper Industry (On-Line System)

- O-frame Instrumentation

Pulp & Paper Industry (Off-Line System)

- Paper Formation Analyzer

Food Processing Industry

- X-ray Imaging based Mango Sorting System

Plastics Industry

- Infragauge system for on-line thickness measurement of co-extruded blown films

- Plastic Waste Sorting System for recycling of Polyethylene Terapthalate (PET) materials

Healthcare System

- A computer aided software tool for microscopic inspection and authentication of herbal medicinal plants

Technologies Developed (2000-10)

Pulp & Paper Industry (Off-Line System)

- Paper Dirt Speck Analyser

Pulp & Paper Industry (On-Line Systems)

- ‘O’ Frame Scanner for Coat Weight Control

- On-line Freeness Tester

Food Processing Industry

- Automation of Rubber Roll Sheller

Plastics Industry

- Infra-gauge with ‘O’ Frame Scanner for Cast Film

Technologies Developed & Transferred (1990-2000)

Pulp & Paper Industry (Off-Line Systems)

- Moisture Gauge

- GSM (Grammage) Gauge

Pulp & Paper Industry (On-Line Systems)

- Low Consistency Monitor

- Stock Consistency Monitor

- ‘C’ Frame Instrumentation for GSM & Moisture

- ‘O’ Frame Scanner for GSM, Moisture & Thickness

- On-line Control for GSM & Moisture

Food Processing Industry

- Viscosity Transmitter for the sugar industry

General Instrumentation

- Programmable Controllers

Technologies Developed (1990-2000)

Pulp & Paper Industry (Off-Line Systems)

- Brightness/Colour Tester

- Tensile Strength Tester

Food Processing Industry

- On-line Brix Meter

Leather Industry

- TANMATE – Leather Tanning Automation System

Technologies Developed & Transferred (1974-1990)

Food Processing Industry

- Vibrotone – Vacuum testing of sealed cans filled with processed foods (NRDC Independence Day Invention Award in 1983)

Chemical Industries

- Autobas –Testing of Battery Separators

- Digital Corrosion Monitor

Leather Industry

- Leather Area Measuring Machine with printer facility

Technologies available for licensing

| Swachh Bharat |

|

| Make in India |

|

| Innovate in India |

|

| Swasthya Bharat |

|

| Clean & Renewable Energy |

|

| Clean India |

|

Usage of plastics is increasing in everyday life. Untreated plastic waste is causing enormous damage to the environment, ecology and public health. Thus, recycling of used plastics is gaining importance and has become a great technological and societal subject. In India at present, most of the plastic waste is being manually graded and recycled into very low value raw material. The manual process is unhygienic and prone to subjective and manual errors. Realizing the importance of the problem, a Near Infrared (NIR) spectroscopy based plastic waste sorting system has been developed.

The system sorts plastic waste materials moving on a conveyor into five types of plastics viz., Poly-Ethylene-Teraphthalate (PET), Poly-Propylene (PP), Poly-Vinyl-Chloride (PVC), Poly-Styrene (PS) and Poly-Ethylene (PE). The system is useful for segregating waste plastics into different value-added polymer fractions for efficient recycling. Aids in easy management of solid plastic waste for recycling. Laboratory prototype has been developed & demonstrated. Technology has been transferred to two entrepreneurs for commercialization.

Salient Technical Features

- Based on Near Infrared Spectroscopy and Chemometric techniques

- Real-time, non-destructive and fast sorting of waste plastics

- Sorts singulated plastics moving on a conveyor

- Sorts 5 types of plastics viz., Poly-Ethylene-Teraphthalate (PET), Poly-Propylene (PP), Poly-Vinyl-Chloride (PVC), Poly-Styrene (PS) and Poly-Ethylene (PE)

- Accurate classification of plastics (near 100% for PET materials)

- Capable of sorting about 100 plastic items per minute or approximately 4 tons of plastics per day.

- Embedded hardware with wireless interface for remote, safe handling and monitoring

- Automated, low cost system using open source hardware and software

- User-friendly Graphical User Interface.

Competing Features

- Automatic, on-line sorting of 5 types of plastics

- Implemented on low cost embedded hardware and open source software

Mango is one of the most important fruits of India with a large annual production. However, India’s share in the world export market is not very significant. One major reason for this is our inability to ensure the quality of mangoes particularly the internal quality. Some Indian mango varieties like alphonso, totapuri and neelam suffer from physiological disorders like spongy tissue and seed weevil which affect their acceptability for internal and export markets. Thus inspection of mangoes for internal defects has great potential in improving the mango exports as well as providing better quality mangoes to the internal market. With this in view, an x-ray imaging based mango sorting system was developed. The system sorts mangoes based on internal defects such as seed weevil and spongy tissue.

Laboratory prototype has been developed & demonstrated to various stake holders. The system is useful for mango growers, processing industries, traders and exporters for sorting of mangoes particularly the export varieties based on internal defects like seed weevil infestation and spongy tissue. The technology may be utilized for other fruits also with suitable modifications. Technology has been transferred to a company for commercialization.

Salient Technical Features

- X-ray imaging system employed for continuous scanning of mangoes

- Integrated with mango sorting assembly

- Specially designed hardware for mango detection and sort control

- Dedicated software modules for image capture, image processing, analysis and sorting

- Image processing methods employed for sorting mangoes

- Image texture analysis and special features extraction to identify the defects

- User interactive menu driven software for calibration and scan settings

Competing Features

- Real-time automated system

- Sorts post-harvested mangoes especially export varieties

- Non-destructive X-ray imaging technique

- No health hazards – safe for consumption

India is the largest producer of the fruits like mangoes, oranges, apples, etc. Sorting of these fruits with respect to their weight has great potential in grading them and in packing them safely to avoid bruises & damages, which will improve their exports as well as providing better customer satisfaction. With this in view, an electronic weighing based fruit sorting system was developed. The system sorts fruits like mangoes, citrus, etc., into several categories based on their weights measured using an electronic weighing arrangement. This will be useful for the fruit processing industry, especially in packing of fruits. A laboratory system was developed and demonstrated. The technology was transferred to a company. A commercial system was manufactured by the licensee and installed at Sri Gajanan Cold Storage and Pack House, C/o. Maharashtra State Agricultural Marketing Board (MSAMB), M.I.D.C., Beed, Maharashtra.

Salient Technical Features

- Singulated fruits moving on a cup conveyor system are weighed dynamically using a specially mounted load cell and sorted into different grades according to user specified weight ranges

- Range: 10 to 4000 gm.

- Accuracy: ± 7.5 gm of full range

- No of sorting stations 4 or 5, extendable

- Throughput: 2 to 3 fruits/sec

The content of Free Fatty Acids (FFA) represents an important quality factor in vegetable oils. CSIR-CEERI Chennai Centre has developed a system for instantaneous and on-line estimation of FFA in sunflower oil. The system uses Near Infrared Spectroscopy (NIRS) and Multivariate Analysis. The NIRS method is non-destructive, instantaneous, cost effective and accurate for estimation of FFA content in sunflower oil. The system was satisfactorily tested for over a one month at the refinery of M/s Kaleesuwari Refinery Private Limited, Chennai.

Features

- PC based system interfaced with a Diode Array Spectrometer and suitable flow cell fitted onto a by-pass line.

- Designed for on-line monitoring and measurement of FFA content in sunflower oil at the end of the oil extraction/refinery process prior to packaging/storing. Tested at a flow rate of 10-12 tons per hour.

- Adaptable to measure both high (5-10%) as well as low values (< 1%) of FFA.

- Accuracy of the tested system is ± 0.02 % FFA.

- User friendly Graphical User Interface (GUI) with following features

- Live data display

- Data-logging

- Bar charts

- Report generation

- Graphical user interface offers multiple access levels. (Admin, Chemist and User).

- System can be easily integrated onto the process line with minimal changes without affecting production.

- Adaptable for other edible oils of different FFA ranges at different process stages and flow rates by suitable modifications & appropriate calibration procedures.

Benefits of the system

- Measurements are instantaneous/on-line without wastage of samples and chemicals.

- Analysis is carried out on captured spectral signatures of the samples and this

- reduces human induced errors

- results in energy reduction

- Results can be utilized in optimizing the process and enhancing the uniform quality of the product.

- System is easy to operate and does not require trained personnel.

- Economically priced with good return value.

- Adds negligible incremental cost on the production.

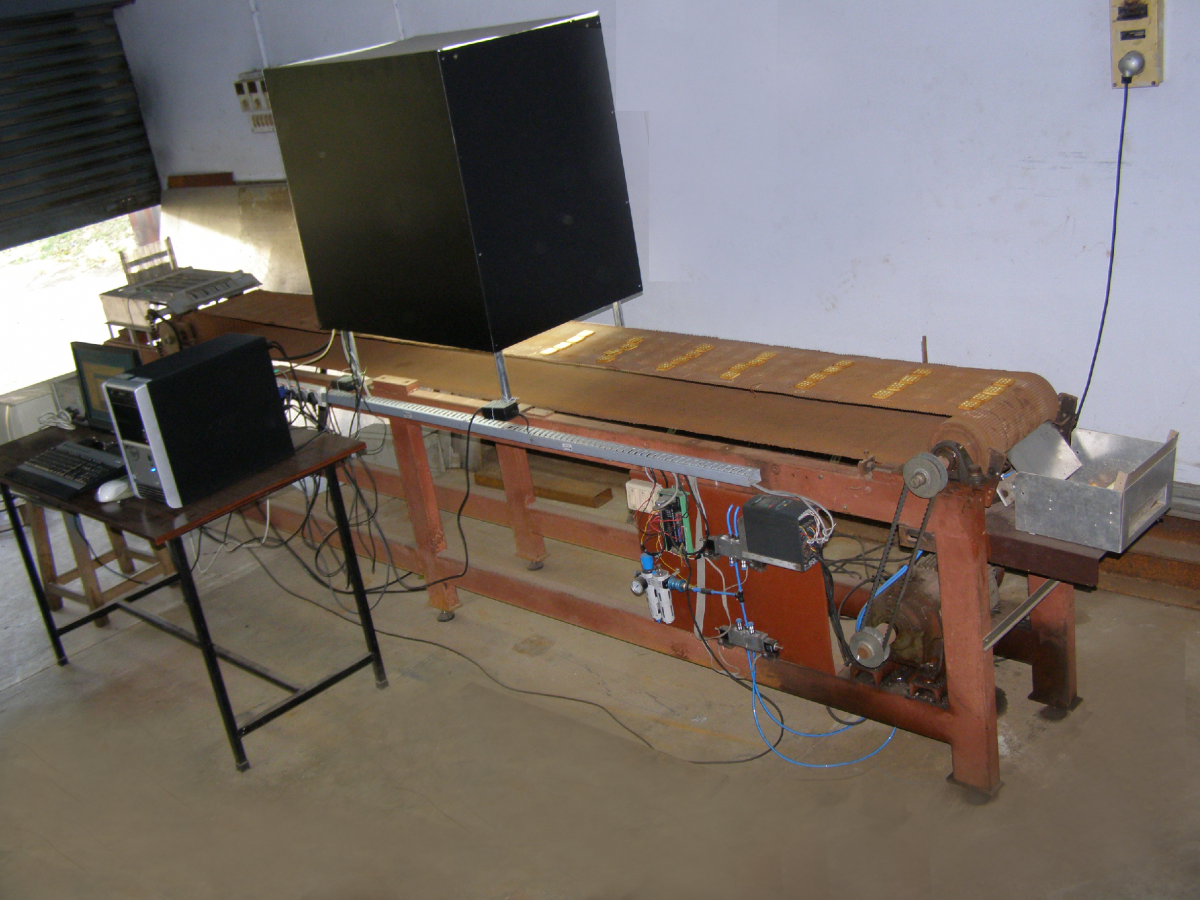

The developed system inspects and sorts biscuits moving on a conveyor based on dimensions and color (baking level). The measurement of colour and dimensions is useful for quality control of bakery products. Measurement of colour of biscuits is useful in optimum setting of the baking oven parameters. Measurement of dimensions is useful in removing damaged, misshapen and over/ under sized biscuits. A laboratory system has been developed and demonstrated to the stake holders. Similar systems are currently not available in the country. Only a few international suppliers from developed countries are catering to the needs of this industry. The developed technology has got the potential for sorting of other bakery products like buns, square/circular biscuits, etc., with suitable modifications in the hardware and software.

Salient Technical Features including Competing Features

- On-line quality inspection of biscuits.

- Measures the colour (baking level in terms of under, normal & over baked) of biscuits.

- Measures the dimensions (length and width) of biscuits.

- Measures the colour and dimensions of the biscuits moving on the conveyor upto a maximum speed of 6 meters/minute.

- Smart camera based embedded system for sorting of biscuits based on colour and dimension.

- Smart camera embeds DSP board and camera for image acquisition and processing.

- Expert decision support system based on artificial neural networks for automated biscuit colour classification.

- Detection and rejection of under/over baked biscuits.

- Rejection of biscuits not meeting dimensional tolerances.

- A supervisory computer system for integrated monitoring.

Fatigue is a problem with severe consequences for drivers and is one of the most contributing cause for the road accidents in India. Existing attempts to implement fatigue detection for automobile drivers have employed several techniques such as blink frequency detection, posture/movement analysis, lane changes etc. However, the reliability of these methods is not very high due to varying lighting conditions and inherent person to person variation. Further, different road traffic and driving conditions makes these methods less accurate in the Indian scenario. Compared to these techniques, physiological measures derived from captured ECG signals give a more accurate assessment of the driver fatigue.

CSIR-CEERI has developed an algorithm using Heart Rate Variability (HRV) as a potential indicator of fatigue. Changes in HRV, especially Low Frequency to High Frequency Ratio (LF/HF ratio) are quantified and a successful correlation has been established with the fatigue level variation. Customized hardware (integrating ECG, PPG sensors and smart cameras) and advanced machine learning algorithms are being developed which can be readily deployed in the vehicles for non-intrusive and accurate fatigue and drowsiness detection and early warning systems for improved road safety.

Salient Features

- Fatigue derived from heart rate variability.

- The computer program performs analysis of the ECG signals in real time and computes pulse rate & heart rate variability and a parameter gives a LF/HF ratio which is correlated to fatigue.

The know-how was transferred to the sponsorer M/s.Tereso Ventures Pvt. Ltd., Pune.

Dual energy X-ray imaging based material discrimination technique was developed to discriminate and identify the materials types (namely Organic, inorganic and metal) in a passenger luggage bag based on atomic number and density values. The developed technique integrated with X-ray Baggage Inspection Systems (XBIS) can be deployed in airports, shopping malls, corporate buildings, hotels and railway stations etc. for passenger luggage inspection to identify concealed materials & substances present inside parcels. XBIS combines the extensive benefits of the scanning process with state-of-the-art image processing.

Salient technical features

- Dual energy image fusion

- Determination of atomic number and density of scanned material items

- Based on atomic number, the material items are labeled and displayed as 3-color & 6-color material discrimination images under different categories namely organic, inorganic and metals

- Separate buttons are provided for image processing functionalities such as image loading, image fusion, 3-color image, 6-color image, density image, organic stripping, inorganic stripping and metal detection.

- Two identical materials of similar thickness belonging to different material types can be segregated.

- Display of density image

- High density region alarm (red alert)

- Algorithm implementation as DLL library

- Hardware security enabled X-ray software

Benefits

- This technology enables industry collaborator M/s.Krystalvision to upgrade their X-ray Baggage scanning machine to next level of commercialization with additional features and cost benefits.

- It has wide application in security and surveillance based Dual-energy X-ray scanning systems.

The know-how was transferred to M/s. Krystalvision Image Systems Pvt. Ltd., Pune, Maharashtra. About 24 scanners were fabricated and installed throughout India by the licensee during 2017-18.

Awards

- Invention Promotion Board Award in 1983 for the Development of Non-destructive Vacuum Measuring System for Canned Food Products (VIBROTONE)

- CSIR-CEERI Chennai Centre won the Runner-up for the 3rd National Award for Technology Innovation 2012-13 from the Ministry of Chemicals and Fertilizers, Govt. of India, for the innovation “On-line Sorting of Consumer Plastic Groups through Near Infrared Spectroscopy” under the category of Innovation in Polymer Waste Management and Recycling Technology and sub-category of Academics and R&D Institution. Dr. Chandra Shekhar, Director, CSIR-CEERI received the Award and Citation from Shri Srikant Kumar Jena, Hon’ble Minister of State (Independent Charge) for Chemicals & Fertilizers; Statistics & Programme Implementation, Govt. of India.

- Dr Bala Subrahmanyam Pesala, Sr. Scientist, got the CSIR Young Scientist Award 2016 in Engineering Sciences.

- CEERI Pilani, FOUNDATION DAY AWARD for recognition of excellence in Technology development and Delivery presented to Dr. R.Govindaraj and Mr.K.Aanadhanarayanan for the project entitled Dual Energy X-ray Image Analysis Technique for Material Discrimination conferred on 21st September, 2018.

List of Facilities Available

Optics & Spectroscopy Facilities:

Fourier Transform Infrared Spectroscopy System (FTIR) : Nicolet 6700

- ATR: Diamond

- Accessories for Transmission, Reflectance and ATR measurements

- Accessories for making palette

- Measurement Range: 6000cm-1 to 650cm-1

- Resolution : 0.125cm-1 to 16cm-1

Optical Microscope -Carl Zeiss Stereo Discovery V20” microscope:

Fourier Transform Infrared Spectroscopy System (FTIR) : Nicolet 6700

- Stereo Zoom and Motorized focus facility (7.5x -520x)

Fluorescence Spectroscopy System (Fluorolog 3/21):

Fourier Transform Infrared Spectroscopy System (FTIR) : Nicolet 6700

- Source: 450-W Xe

- Excitation monochromator- Double

- Emission monochromator- Single

- Detector: PMT

- Grating : 1200g/mm

- Excitation wavelength range:200-950nm

- Emission wavelength range: 200-950nm

- Photon Counting electronics and controlling software

- Experiment types: Emission, Excitation, Synchronous

- Measurement type: Steady State, Lifetime

Flame-NIR INTSAMA25 Spectrophotometer:

- 950-1650nm

- Source: HL-2000-LL (360nm-2000nm)

Fiber Optic Spectrometer NIR-256-1.7 Tec:

- Avalight-HAL-10w Tungsten and Reflecton Probe FCR-71R400

Software:

- Thermo Scientific OMNIC Software Suite Ver 8.3

- Unscrambler 10.5.1

- OriginLab2020

Terahertz Lab Facilities:

Terahertz time-domain spectroscopy (THz-TDS) system

- Time resolution - minimum ~ 0.01 ps

- Frequency range – upto 3 THz

- Dynamic Range – 60 dB

Terahertz Continuous Wave (THz CW) imaging system

- Frequency range - 0.1 to 0.4 THz

- Dynamic range - 80 dB dynamic range @ 0.1 THz (with Schottky diode receiver)

Optical Spectrum Analyzer (OSA)

- Wavelength range: 600 to 1700nm

- High wavelength accuracy: ±0.01nm

- High wavelength resolution: 0.02nm

Terahertz High-speed imaging camera

- Sub THz IMPATT diode source @ 0.1 THz with 80mW

- 1D array of 256 GaAs detectors

- Image acquisition rate: 5 kHz

Machine Vision and Imaging Facilities

Monochrome Machine Vision Camera with C-Mount Lens

- Model No : IDS-UI-3240CP-NIR-GL

- Make : IDS Imaging Development Systems

- Sensor type : CMOS Monochrome

- Resolution : 1.31 Mega Pixels

- Aspect ratio : 5:4

- Colour depth : 12 bit

Colour Machine Vision Camera with C-Mount Lens – 2 Nos

- Model No : IDS-UI-3280CP-C-HQ

- Make : IDS Imaging Development Systems

- Sensor type : CMOS Colour

- Resolution : 5.04 Mega pixels

- Aspect ratio : 5:4

- Colour depth : 12 bit

Visual Studio Professional 2015 with MSDN (Single User license)

Area Scan Colour CMOS Camera

- Teledyne Dalsa Genie Nano C2420 2/3" Color GigE Camera

- Power Supply, I/O Cable, 5m GigE Cable and sapera LT SDK (Navitar MNV16M23 16mmLens-1No, TMS Lite LBRQ White with Cable set-1No Analog AC to DC Controller 2 Channel-1No

Area Scan Monochrome CCD Camera

- “DALSA" Pantera Camera Area Scan , 1024 X 1024 Resolution, 60fps, 12 Bit Camera link, M42 mount Pantera !M60 family

GiGi Camer

- AVT-E0020513 G095C Camera

Cameralink Camera

- Progressive scan CCD JAI camera – 2 Nos